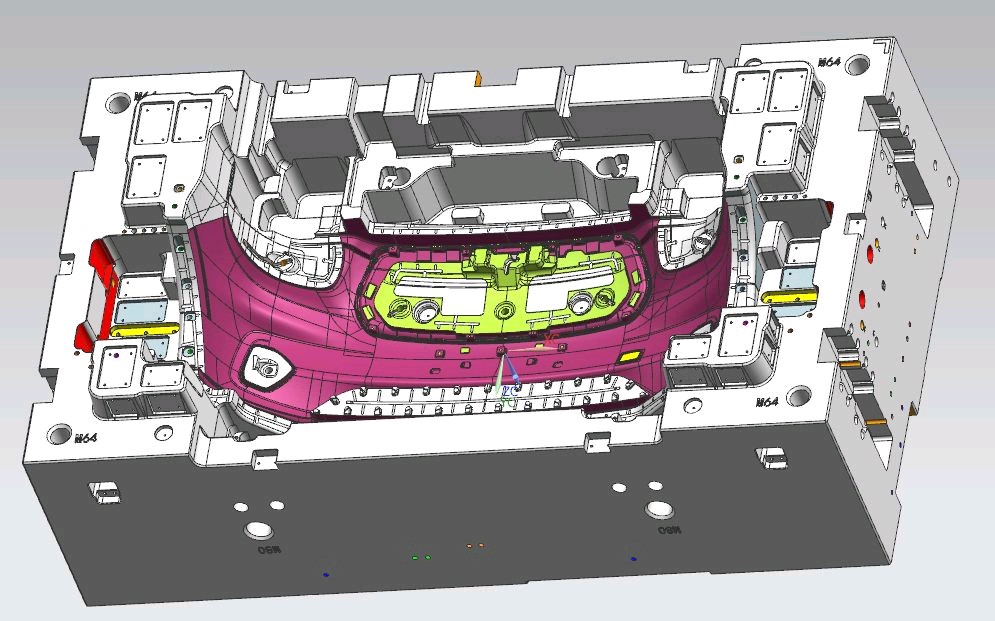

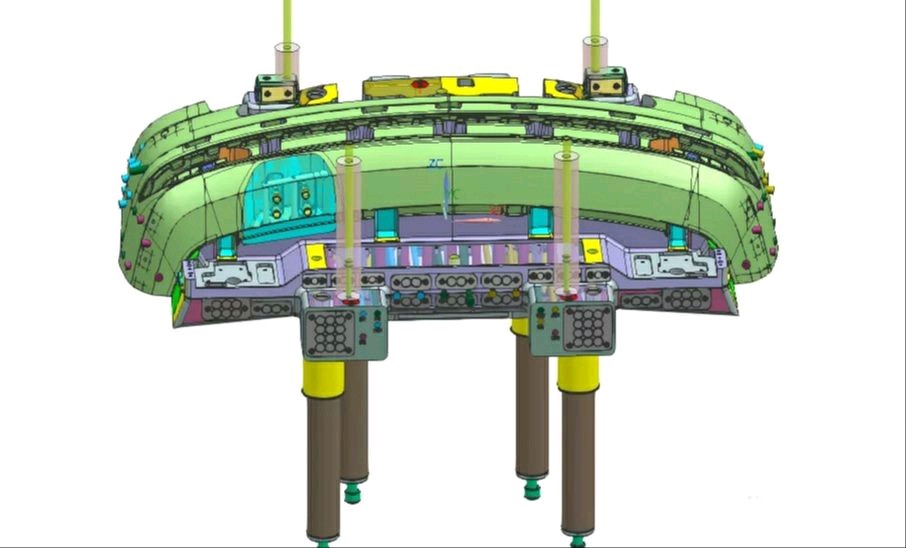

Automobile molds is a product we see every day, which is used in various interior and exterior decorations of automobiles, such as plastic bumpers, shock absorbers, instrument panels, etc. Therefore, we cannot let go of any detail during processing.

Automobile injection molds have much higher requirements for processing equipment than traditional injection molding. There are generally two methods for processing.

*1.

Use the mirror spark machine for processing, just to ensure the high precision of the product, it is best to use the graphite electrode for EDM processing, because the loss of the graphite electrode is much smaller than that of the ordinary copper electrode.

*2.

The most commonly used processing method is the electroforming mold. The electroforming process can ensure that the mold has good precision, but the disadvantage is that the processing time is relatively long, and each hole must be processed independently. One is that once minor damage occurs during the production process, it cannot be repaired, and the damaged acupoints can only be replaced.

In terms of molds, mold temperature is also a very important parameter for auto parts molds. Auto parts mold processing faces consumers with high-end needs. Now we generally use the concept of high-gloss injection molding and introduce rapid heating and cooling systems.

Generally speaking, high mold temperature is very helpful for auto parts molds. For example, it can prevent the difficulty of thin-wall filling and lack of material, but because too high mold temperature will bring new problems, that is, cycle lengthening and the problem of shrinkage and deformation after mold opening.

Then it is very important to introduce a new mold temperature control system at this time. During the injection molding process, the mold temperature can be increased, so that the melt can fill the cavity faster and prevent the melt temperature from dropping too fast during the filling process. However, the filling is incomplete, and when the mold is demolded, the mold temperature can be rapidly reduced, kept at a temperature slightly lower than the plastic thermal deformation temperature, and then the mold is opened and ejected.

Whether it is in the processing or design of auto parts molds, Chapman can provide auto suppliers with better quality auto interior and exterior trim molds. The Chapman design team can effectively and accurately analyze the feasibility of the product in the early stage according to the customer’s requirements. Weld lines can be avoided in advance, and the designed mold has a good cooling system, exhaust system and optimal injection system.

If you need excellent auto interior and exterior trim molds, please contact us through the following ways for further understanding. For more information, you can also follow our website, we are always online to help you.

Email: info@chapmanmaker.com

Post time: Jun-08-2022